Technical features

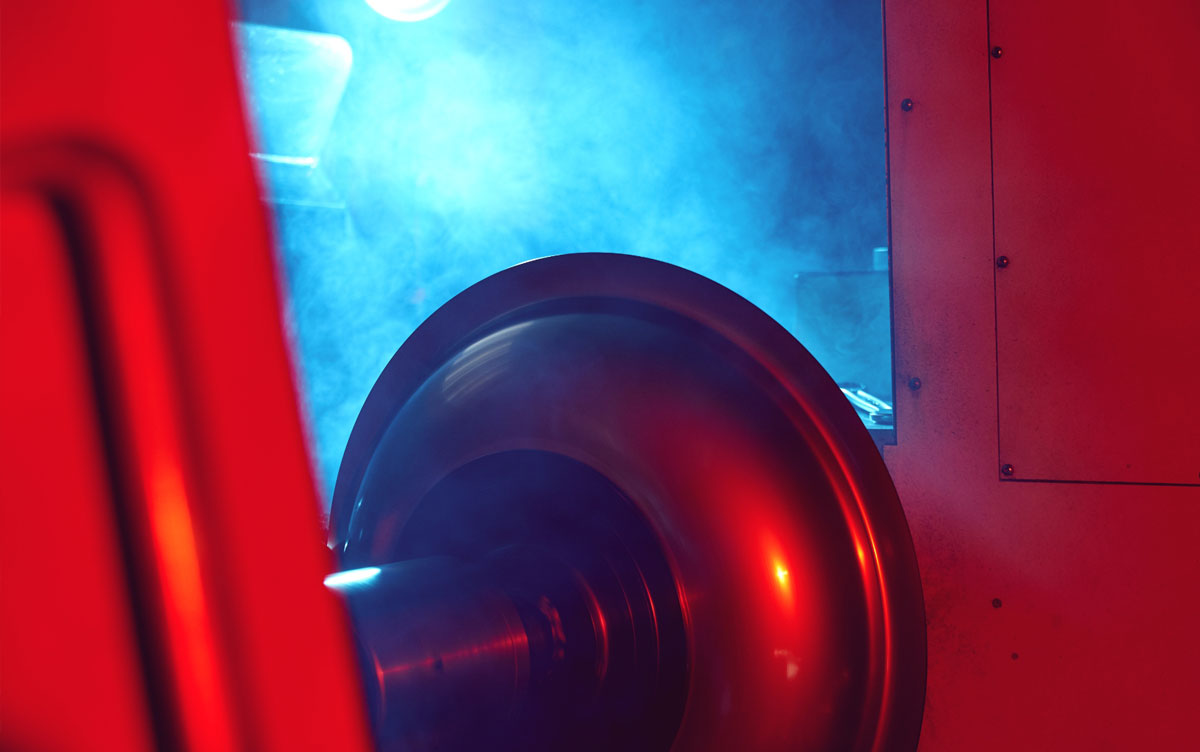

Spin forming (or lathe drawing) is a machining technique that makes it possible to deform sheet metal into rounded, hollow, axially symmetrical products by machining a flat metal sheet on a lathe.

This type of machining is used to create a detail that in turn will be incorporated into a larger object. Spin forming makes it possible to create different shapes and special details for different sectors, from furnishing to mechanical engineering and much more.

First, the mould (or die) is produced from the solid material, which will be used as a template for subsequent machining. This die will be adhered to the metal in order to model it and create the actual object.

The mould and metal sheet will then be assembled on the alphanumerically controlled spin forming machines, by means of a roller. A qualified operator ensures that the sheet metal adheres perfectly to the mould in order to obtain the object as it was intended in every detail.

After machining, all the moulds are stored in our warehouse with maximum customer confidentiality.

Spin forming makes it possible to create different shapes and special details at a low cost. This is because it is thanks to the highly specialised personnel working on state-of-the-art machines that we are able to offer precision in production and punctual delivery of the materials.

The machining dimensions range from a minimum machining thickness of 0.5 mm to a maximum of 3 mm. The maximum diameter of the finished product is 1 metre.

Spin forming makes it possible to machine different types of materials, from those that are more flexible such as copper, iron, brass and aluminium to those that are tougher such as stainless steel.

Our highly efficient numerically controlled (CNC) machinery makes it possible to create products obtained from bars of different types of metal for diameters of up to 1000 mm.

Thanks to this machining method, numerous advantages can be achieved and an excellent customer-oriented service can be offered.